ICR's work in industrial acoustics is basically focused on offering our advice to solve the problems of industrial noise and vibrations that may arise during the development phase and the finalization phase of the product.

Working Procedure

During the development phase, ICR facilitates the optimization of resources (time and money) through advice and the proposal of appropriate modifications. The objective at this stage is to improve the performance of the products, placing special emphasis on their acoustic and vibratory qualities.

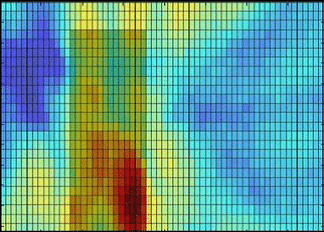

At the product completion stage, whether the problem is the factory or the indoor machines, ICR applies model inversion methods to obtain the acoustic power (SWL) of all industrial noise and vibration sources. This methodology allows us to quantify and classify the most problematic noise sources and in this way calculate the necessary improvements to be applied to each one in order to reach the target noise levels.

Services

Some services offered in the field of industrial acoustics are:

-Inversion models applied to the obtaining of the acoustic power from noise and/or vibration sources in order to quantify and order the level of noise generated by each noisy equipment without the need to alter its operation.

-Development of numerical models to simulate the vibroacoustic behaviour of an industry and verify compliance with current regulations.

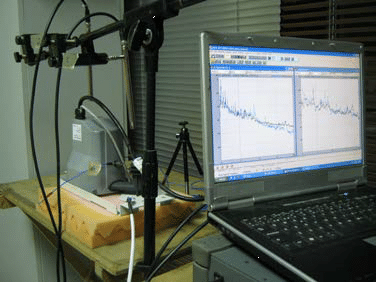

-Study of the vibroacoustic behaviour of long tubes.

-Transmission pathways applied to industrial noise and vibrations.

-Machine noise forecasting and measurement.

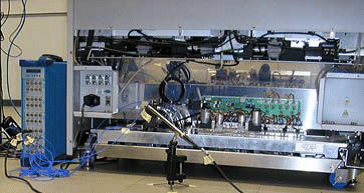

-Gear noise prediction and measurement.

-Quality control in production line.

-Design of silencers, enclosures and acoustic barriers.